We are excited to announce that MER-Europe will be attending the first-ever edition of Medical Technology Germany, taking place in Ulm.

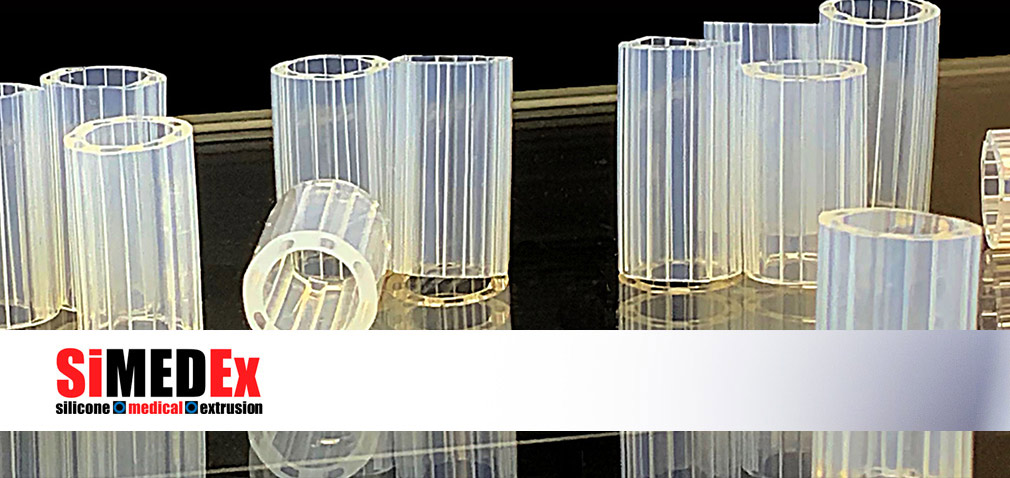

As your trusted partner representing a broad network of leading medical technology suppliers, we will be on-site to showcase their latest developments and capabilities, ranging from Metal Laser Cut Tubes to support Steerable Catheters to Multi Lumen Silicone Tubing for CRM applications.

We are also pleased to share that Bob Madigan from our valued partner MDC-Lighteum will be present at the fair. This is a unique opportunity to meet Bob in person and learn more about MDC and particularly Lighteum’s expertise in Nitinol component design and manufacturing.

Whether you are just starting your development process or looking for support in scaling up production, we invite you to schedule a meeting with us to discuss your project needs. If you need coatings, silicone extrusions, silicone molded parts, precious metal tubing & wire, nitinol tubing, flat sheet… Let’s connect in Ulm — we look forward to meeting you!

📍 Medical Technology Germany – First Edition

📅 9-10 July, 2025

📌 Stand 154, Ulm-Messe, Germany

👉 To set up a meeting, please contact us via info@mer-europe.com or call +31 (0)653 608 920.