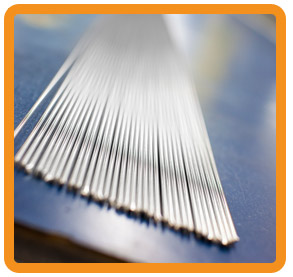

In the development of medical devices, one of the main challenges is getting the material characteristics right. Specific applications require specific material behaviour.

In the development of medical devices, one of the main challenges is getting the material characteristics right. Specific applications require specific material behaviour.

When working with metal components, one learns that stainless steel isn’t ‘just’ stainless steel. Different alloys have been composed, allowing the user to match their parts with the required strength, temperatures, corrosion resistance etcetera for their application.

But which alloy works best for you? K-Tube Technologies’ engineering team are experts in the field of medical applications. They can help with designing custom tubing and advise in raw material selection for your specific tube application.

K-Tube offers the following options in Stainless Steel alloys:

304/304L

304/304L grade stainless steel is an alloy with chromium-nickel. It is widely used and readily available. It is also the most economic grade of SS. 304/304L can be deep drawn and does not require intermediate annealing. Applications include needles & syringes, catheters, surgical instruments etc.

316/316L

316/316L grade stainless steel is another commonly used alloy, containing chromium-nickel and low carbon content which increases its resistance to intergranular corrosion after welding. Biocompatibility is well tested and the material is also suiteable for saltwater applications.

Applications include catheters, suture wires, surgical stylets, bone pins etc.

17-7PH®

17-7 PH® can be hardened by heat treatment. It is a PH (precipitation hardened) stainless steel with higher tensile strengt hand hardness compared to the 300 serie, especially when heat treated. Applications include catheters, biopsy needles and needles with increased stiffness.

*17-7 PH® is a registered trademark of AK Steel Corporation.

I-625®

Inconel® 625 is a stainless steel alloy with a chromium-nickel and low carbon content. Its corrosion resistance is remarkable, especially at higher temperatures. I-625® is MRI compatible. K-Tube manufactures I-625® tubing for MRI compatible needles, high temperature probes, aerospace and nuclear applications.

Inconel is a registered trademark of Huntington Alloys Corporation.

MP35N®

MP35N® is an alloy containing nickel-cobalt-chromium-molybdenum. It has unique properties such as a very high tensile strength & hardness as well as ductility when cold-worked, making this the go-to alloy for applications where others have failed. Applications include biopsy needles, MRI compatible needles, delivery systems and stents.

MP35N is a registered trademark of SPS Technologies, LLC.

Datasheets of the different materials are online available. Also, K-Tube is capable of producing tubing from additional alloys. Currently they have inventory of: 321, 347, 410, 420, 430, Hanyes 276, L605, Eligiloy, 1RK91, Inconel 718, Kovar, Hymu, Alloy 52.

AND coming soon: Titanium Grades 1-4, 9! (Titanium is in development, please inquire for more information).

If you need an alloy that is not listed, please let us know. We are happy to assist in finding the right material for your application!

Contact MER-Europe and find out more. We are dedicated to provide quick answers and high quality engineering solutions.

Manufacturers Representatives | Technical Link| Engineering Solutions & Support